Slurry pumps are typically larger in size than standard pumps with more horsepower and built with more rugged bearings and shafts. Slurry pumps should be supplied together with mineral processing equipment thus providing for the first time a complete package.

Pump Boxes Slurry Pumps Alberta Oil Sands Equipment

The preferred method for packing a slurry pump is the flush seal shown in Figure 13-5a.

. An efficient TBM slurry separation plant is the basis for the successful use of slurry-supported tunnel boring machinesTBM. If you are not sure about the type of slurry the choice of pump the design of the pipe system. It has a high-pressure seal that moves inside the cylinder.

JHB Concentrated Sulfuric Acid Submerged Pumps. Box 12145 Green Bay WI 54307 Phone. 64 H Slurry pump.

32 H Slurry pump. Box before slurry pumping at mining industry. Ad Heavy-Duty USA Built Slurry Pumps Built For Solids up to 70 by Volume.

A stuffing box separates the non-rotating parts from those that rotate. The licence agreement - signed by Sala was for an English design the Vac-seal slurry pump. Heavy duty slurry pumps.

Describe slurry pumps slurry pumping and the various parameters required when selecting submersible slurry pumps using FLYPS. Light duty slurry pump. Our pump boxes can be customized to handle any project regardless of size or scope.

They separate out oversized solids to create a slurry. 215 H Slurry pump. JLF Vertical Slurry Pumps.

It is a fluid-dynamic pump with no moving. JHXL Dirty Sulfur Pumps. 1210 H Slurry pump.

Enters the two impellers to continue to pressurizethereby obtaining a higher lift. Compared with conventional water pumps the above requirements result in a larger pump that is less. 43 H Slurry pump.

Clean water is injected into the stuffing box to flush solid particles away and to cool and lubricate the packing and shaft sleeve. To provide a deeper understanding of the calculations a manual calculation example is given in the appen-dix of the book. Bergkamp Slurry Seal Spreader Box Specifically designed for Slurry Seal applications Available in these widths.

Ad Reliable Cost-Effective Heavy Duty Pumps Dredges For Dozens Of Industries. A pump that is becoming increasingly popular for handling slurry and slime is the Grit Pump made by International Combustion Ltd. Hopper barges have funnel shaped holds that can be emptied through the bottom of the vessel.

Open While slightly less efficient open impellers work well for slurry that contains a combination of fluids solids and. High head slurry pump. Every part of the pump in contact with the slurryintake piping pumping chamber and impellercan if necessary be rubber-lined.

In addition the radial feed design is adopted so that the pressure at the sealed box is equivalent to the impeller. Tapflo pumps - long life design and robustness. OptiFlow Design and Build Center 1002 Truman Street Kimberly WI 54136 920-733-4425.

Hydraulic Design of a Slurry Distribution Box 21. Non-clog and Low Maintenance Pump Objects up to 11-in in Diameter. In the early 60s Sala developed a new range of medium duty slurry pumps.

Slurry pump box design Ditulis Jesus Randall Jumat 10 Juni 2022 Tulis Komentar Edit. If the particle size falls between 04 and 05 microns then you can attain the proper slurry concentration at around 40 below static settled. Typical Diagram for Open Channel Tailings System TERMINAL STATION INTERMEDIATE VALVE STATION PRESSURE MONITORING STATION PUMP.

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. Closed For those seeking high efficiency closed impellers are best. By maintaining the right level of slurry concentration consistency you can ensure the product moves through your system at a productive rate.

Distribution boxes are designed with a number of chambers and hydraulic controls to ensure thorough mixing of the incoming slurry streams and even distribution to each outlet of volumetric flow rate solids concentration and particle size while maintaining stable flow. Typical Diagram for a Tailings Pipeline System with centrifugal pumps. They must be able to pump high-density abrasive slurries while maintaining reasonable wear life.

JHG Specialized Vertical Concentrated Sulfuric Acid Pumps. Slurry pump box design Written By doering Tuesday May 24 2022 Add Comment Edit. 86 H Slurry pump.

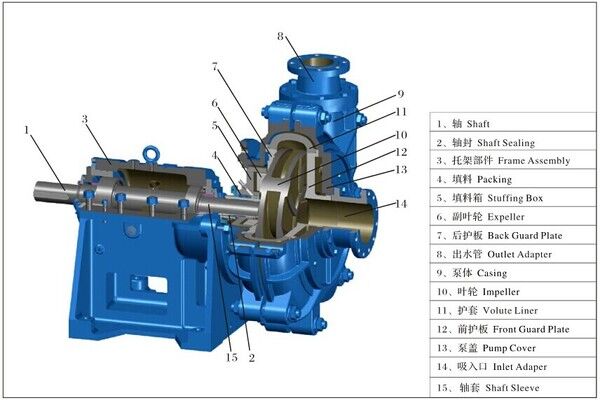

1412 H Slurry pump. When it comes to centrifugal slurry pump maintenance a stuffing box is the best option for time-sensitive issues that may arise. Slurry pump stuffing box is one of shaft seal parts in gland packing seal pumps where the packing is housed in.

First of all slurry pumps should be designed for specific operating requirements. In most cases this system will include a launder or an energy dissipating drop boxes along the delivery route see Figure 3. For these reasons soft compression packing is still favored as a means of sealing at the stuffing box.

The packing area of stuffing box is longer than expeller ring so it can contain more packing. Of course the number of rings of packing will depend on the design of the stuffing box and that will determine how to pack your pump. Slurry pump box.

The most common type of slurry pump is the centrifugal pump. Slurry pump box design. 108 H Slurry pump.

Heres a rundown of slurry pump components and options. These pumps use a rotating impeller to move the slurry similar to how a water-like liquid would move through a standard centrifugal pump. WEIR SLURRY PUMPING MANUAL iv1 Symbols used The terms slurry and mixture in this Manual are used interchangeably to describe a mix of any loose solids made up in any proportions and combinations of any particle sizes and any conveying liquidThe subscript w refers to densities and specific gravities of liquids mostly but not exclusively water.

Pump boxes or slurry pumps are used across the mining and oil and gas industries. Impeller Surrounding the pump shaft the impeller energizes the slurry being moved. JHL Molten Sulfur Pumps.

300ff L Slurry Pump Stuffing Box Rsl30078 D21 Pumps Box Do Your Best Patented and superior design features minimize life-cycle costs. 151 H Slurry pump. This ensures your materials can be transported through pipelines to their end destination.

Slurry pumps can be divided into horizontal slurry pumps and vertical slurry pumps according to the position of pump shaft and water level. The original model is shown in section in Fig. They must also be able to pass large solids.

9 to 14 feet 27 to 43 m 10 to 15 feet 30 to 45 m 11 to 16 feet 33 to 48 m Adjustable in 6-inch 15 cm increments Bergkamp Spreader boxes are compatible. Slurry pumps are often subjected to severe shock loading and shaft whip due to the presence of solids and system upsets. Slurry Pump Box Design.

Differences Between Flush And Quench In Slurry Pump Seal Support Plans

China 1 5x1b Small Slurry Pump Warman 1 5x1 Pump 1 5 1 Ah Warman Pump

Pump Boxes Slurry Pumps Alberta Oil Sands Equipment

New Pump Box For Sale By Savona Equipment

0 comments

Post a Comment